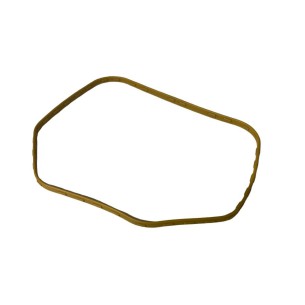

Oil filler cap on Kohler KDI rocker cover

The oil filler cap on the rocker cover for Kohler KDI engines is an essential component in the lubrication system of these engines. This element allows access to the lubrication system, making it easier to fill and monitor the oil level, which is crucial for proper engine operation.

Product Features

- Specific design for Kohler KDI engines.

- Made with materials that guarantee adequate watertightness.

- Compatible with a variety of industrial and agricultural applications.

Compatibility

This plug is compatible with Kohler KDI series engines, which are used in a variety of applications, including agricultural machinery, generators, and construction equipment. Its design has been optimized to fit perfectly into the rocker cover, ensuring an effective seal and preventing oil leaks.

Applications

The oil filler cap is used on a wide range of machinery and equipment that require Kohler KDI engines. Some of the most common applications include:

- Agricultural tractors.

- Electric generators.

- Construction and public works equipment.

- Gardening and landscaping machinery.

Maintenance and care

To ensure proper engine operation and prolong its lifespan, regular maintenance of the lubrication system is essential. This includes checking the oil level using the filler cap and replacing the oil according to the manufacturer's recommendations. A cap in good condition is crucial to prevent contamination and maintain the integrity of the lubrication system.

Advantages of using the oil filler cap

- Facilitates access to the lubrication system, allowing for easier maintenance.

- It helps prevent oil leaks, which is essential for optimal engine performance.

- Its specific design ensures correct adaptation to Kohler KDI engines, avoiding compatibility problems.

Conclusion

The oil filler cap on the rocker cover for Kohler KDI engines is a critical component that ensures proper lubrication system maintenance. Its design and compatibility with a wide range of industrial and agricultural applications make it key to the efficient operation of engines in this series. Maintaining this component in good condition is essential to ensure engine longevity and proper performance.