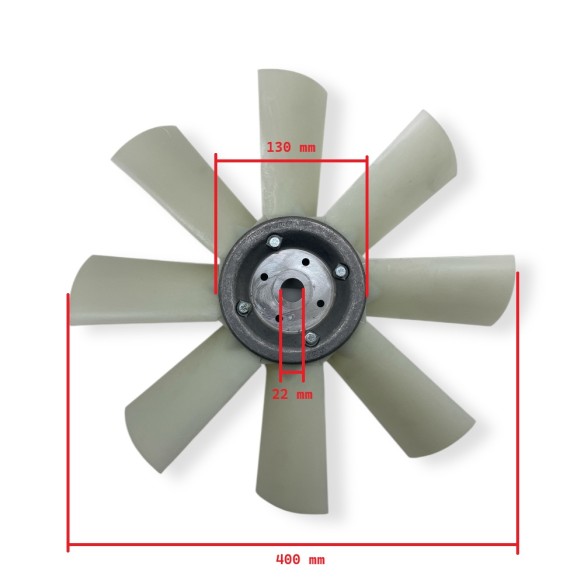

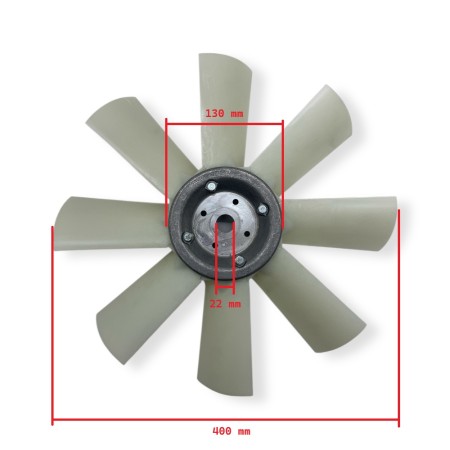

400mm Kohler-Rehlko KDI and Lombardini LDW fan

The 400 mm fan is an essential component designed for use in industrial and agricultural engines, specifically in Kohler-Rehlko KDI and Lombardini LDW models. This element is fundamental to the engine cooling system, ensuring adequate airflow that contributes to regulating operating temperature.

Compatibility

This fan is compatible with a variety of motors, making it a versatile option for different applications. Specific compatible models are listed below:

- Kohler-Rehlko KDI

- Lombardini LDW

Applications

The 400 mm fan is used in a variety of industrial and agricultural applications where efficient engine cooling is crucial. Some of the most common applications include:

- Agricultural machinery

- Construction equipment

- Electric generators

- Commercial vehicles

Technical Characteristics

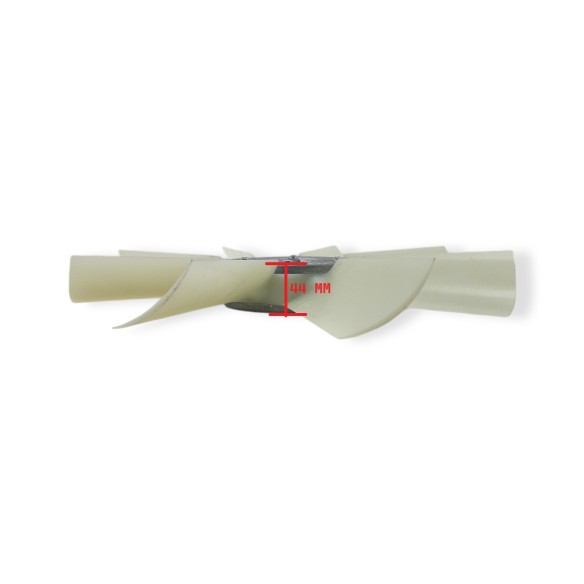

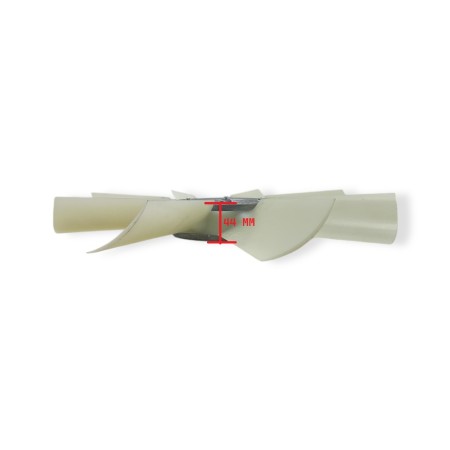

This fan is designed to provide optimal airflow, which is essential for maintaining engine temperatures within the proper range. Its design allows for easy installation and efficient operation under demanding conditions. Technical features include:

- Diameter: 400 mm

- Construction material: designed to withstand adverse conditions

- Aerodynamic design: optimized for efficient airflow

Maintenance and Care

To ensure proper fan operation, regular maintenance is recommended. This includes cleaning the blades and checking their overall condition. Proper maintenance helps prolong the component's lifespan and ensures its proper functioning in the engine cooling system.

Final Considerations

The 400 mm fan is a key component in the cooling system of Kohler-Rehlko KDI and Lombardini LDW engines. Its design and compatibility with various models make it an ideal choice for those looking for a reliable replacement. Attention to detail in its manufacturing ensures it meets the demands of industrial and agricultural environments, providing adequate airflow for proper engine operation.

In short, this fan is an effective solution for maintaining engine temperatures at optimal levels, thus contributing to the optimal performance of the machines in which it is installed. Its versatility and technical design make it indispensable for engine maintenance in a variety of applications.