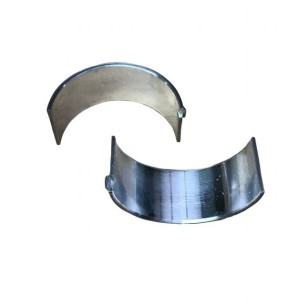

Crankshaft bearing -0.50 Lombardini 12LD477-2, 25LD330-2, 25LD425-2

The crankshaft bearing is an essential component in engine mechanics, designed to provide proper support for the crankshaft and allow for smooth, efficient rotation. This specific model is compatible with several Lombardini engines, including the 12LD477-2, 25LD330-2, and 25LD425-2 models, making it a versatile choice for a variety of industrial and agricultural applications.

Model Compatibility

- Lombardini 12LD477-2

- Lombardini 25LD330-2

- Lombardini 25LD425-2

Applications

This bearing is used in engines across a variety of sectors, including agricultural machinery, generators, and industrial equipment. Its design allows for efficient integration into systems requiring continuous and reliable operation. The choice of this component is crucial to maintaining engine integrity and ensuring proper operation under a variety of operating conditions.

Technical Characteristics

The crankshaft bearing is made of materials that guarantee adequate resistance to wear and engine operating conditions. Its design is optimized for easy lubrication, which contributes to prolonging the life of the component and the engine in general. This type of bearing is essential for minimizing friction between moving parts, helping to maintain engine stability during operation.

Importance of the Crankshaft Bearing

The crankshaft bearing plays a crucial role in engine mechanics, supporting the loads generated by combustion and crankshaft movement. A bearing in good condition is vital to prevent engine damage, as failure in this component can lead to premature wear or even crankshaft failure. Therefore, proper maintenance and bearing replacement when necessary are essential to ensure engine longevity.

Considerations for Selection

When selecting a crankshaft bearing, it's important to consider compatibility with the specific engine model. Additionally, the type of application and operating conditions the engine will be subjected to must be taken into account. The correct bearing selection not only affects engine performance but also the overall efficiency of the system in which it is integrated.

Maintenance and Replacement

Regular crankshaft bearing maintenance is essential to ensure proper operation. Periodic inspections are recommended for signs of wear or damage. If problems are identified, it is advisable to replace the bearing to prevent major engine failure. Attention to these details can make a difference in the durability and performance of the equipment.

Conclusion

The -0.50 crankshaft bearing is a key component in Lombardini 12LD477-2, 25LD330-2, and 25LD425-2 engines. Proper selection and maintenance are essential to ensure optimal engine performance and extend its life. Attention to detail when selecting this type of replacement can significantly contribute to the reliability and effectiveness of the applications in which it is used.