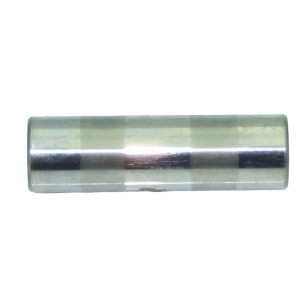

Cylinder head gasket 1.80 - 2 notches Lombardini LDW 1503, LDW 1603

The cylinder head gasket is an essential component in Lombardini diesel engines, specifically designed for the LDW 1503 and LDW 1603 models. This element seals the joint between the cylinder head and the engine block, ensuring system tightness and preventing fluid leaks. Its design includes two notches, allowing for precise adaptation to the specifications of the aforementioned engines.

Compatibility

This replacement part is compatible with the following Lombardini engine models:

- LDW 1503

- LDW 1603

Materials and Construction

The gasket is made of materials that ensure adequate resistance to the high temperatures and pressures generated inside the engine. Its construction is designed to withstand demanding operating conditions, providing an effective seal that prevents oil and coolant mixing, as well as compression loss.

Main Functions

- Sealing: Prevents leaks of gases, oil and coolant between the cylinder head and the engine block.

- Tightness: Maintains the appropriate pressure in the combustion system, contributing to the correct functioning of the engine.

- Protection: Prevents premature wear of internal components by ensuring effective sealing.

Applications

The cylinder head gasket is a critical component in industrial and agricultural applications where Lombardini engines are used. Its use is common in heavy machinery, generators, and farming equipment, where engine reliability is critical to the continuous and efficient operation of operations.

Maintenance and Replacement

It's advisable to periodically inspect the condition of the cylinder head gasket, especially on engines that operate under severe conditions. Timely replacement of this component can prevent further engine damage and ensure its longevity. Detecting coolant or oil leaks may indicate that the gasket needs to be replaced.

Conclusion

The 1.80-2 notch cylinder head gasket is an essential component for the proper functioning of Lombardini LDW 1503 and LDW 1603 engines. Its specific design and high-strength materials ensure effective sealing, contributing to engine durability and reliability in a variety of applications. Maintaining its condition and replacing it properly are essential to maintaining the integrity of the propulsion system.