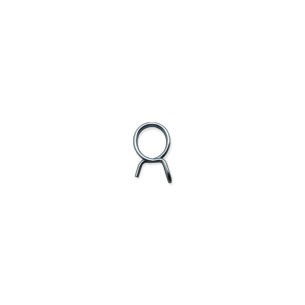

Diesel pipe clamp 10.5mm Lombardini 15LD Kohler-Rehlko KD15

The 10.5 mm diesel fuel line clamp is an essential component in fuel line systems, specifically designed for use on industrial and agricultural engines. This fitting is compatible with specific models, ensuring a secure and efficient connection when installing fuel lines.

Compatibility

This clamp model is compatible with Lombardini 15LD and Kohler-Rehlko KD15 engines. Its design has been optimized to fit the specifications of these engines, ensuring proper integration into the fuel system.

Applications

- Fuel supply systems in diesel engines.

- Connections in agricultural machinery and industrial equipment.

- Diesel fuel piping installations in commercial vehicles.

Materials and Construction

The clamp is made of materials that offer resistance to corrosion and adverse environmental conditions. Its robust construction allows for a firm hold, preventing leaks and ensuring the integrity of the fuel system. This type of clamp is essential for maintaining the safety and functionality of diesel installations.

Technical Characteristics

- Clamping diameter: 10.5 mm.

- Specific design for Lombardini and Kohler-Rehlko engines.

- Manufactured in corrosion-resistant materials.

Maintenance and Durability

The diesel fuel line clamp requires minimal maintenance, making it a practical choice for industrial and agricultural applications. Periodic inspection is recommended to ensure there are no signs of wear or damage, which could compromise the functionality of the fuel system.

Advantages of the Clamp

- Facilitates the secure connection of diesel pipes.

- Helps prevent leaks in the fuel system.

- Compatible with engines from renowned brands, ensuring versatility in use.

Final Considerations

The 10.5 mm diesel fuel line clamp is a key component in the installation and maintenance of fuel systems on Lombardini 15LD and Kohler-Rehlko KD15 engines. Its design and materials ensure an effective connection, contributing to the operational efficiency of agricultural and industrial machinery. For optimal performance, it is essential to select the appropriate clamp and regularly monitor its condition.