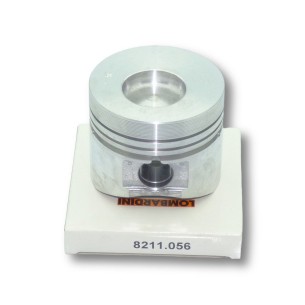

Lombardini LDA, 3LD, 4LD, 6LD filling cap

The filler cap is an essential component in Lombardini LDA, 3LD, 4LD, and 6LD series engines. This element is designed to ensure safe and efficient closure of the fuel or oil filling system, preventing leaks and external contamination. Its specific design allows for optimal integration with the aforementioned engines, ensuring proper operation in various industrial and agricultural applications.

Compatibility

This plug is compatible with the following Lombardini engine models:

- LDA

- 3LD

- 4LD

- 6LD

Compatibility with these models ensures a perfect fit, maintaining the integrity of the filler system and contributing to proper engine operation.

Materials and Construction

The cap is made with selected materials that guarantee adequate durability under demanding operating conditions. The cap's construction allows for resistance to corrosion and temperature variations, which is essential for use in industrial and agricultural environments. Its design includes a sealing system that prevents the entry of impurities and fluid loss, thus ensuring engine protection.

Applications

This component is used in a variety of applications requiring internal combustion engines. Lombardini engines are commonly used in agricultural machinery, electric generators, and construction equipment. Proper installation of the filler cap is crucial to maintaining engine functionality and preventing problems related to the lubrication or fuel system.

Maintenance and Replacement

Maintaining the filler cap is essential to ensure engine longevity. Periodic inspections are recommended to verify the condition of the cap and its sealing system. If wear or damage is detected, it is advisable to replace it to prevent engine malfunctions. Easy access to this component allows for quick and efficient replacement, minimizing equipment downtime.

Conclusion

The filler cap for Lombardini LDA, 3LD, 4LD, and 6LD engines is a key component that contributes to engine performance and protection. Its specific design and high-strength materials ensure a perfect fit and effective sealing, which is essential for proper operation in a variety of applications. Attention to maintenance and prompt replacement, if necessary, are recommended practices to maximize engine life and ensure its performance over time.