Lombardini motor foot LDW 502, 602, 702, 903, 1003, 1204 and 1404

The engine mount is an essential component in the structure of Lombardini engines in the LDW 502, 602, 702, 903, 1003, 1204, and 1404 series. This element provides the necessary support for the engine, ensuring its proper fit and stability during operation. Below is a detailed description of this component, including its applications and compatibility.

Product description

The engine mount is designed to fit a variety of Lombardini engine models, ensuring proper integration into different systems. Its robust design keeps the engine in place, minimizing vibrations and contributing to the durability of the engine assembly.

Compatibility

- LDW 502

- LDW 602

- LDW 702

- LDW 903

- LDW 1003

- LDW 1204

- LDW 1404

This motor mount is compatible with the aforementioned models, making it a versatile option for those using Lombardini engines in industrial and agricultural applications. Its specific design ensures a perfect fit for each model, facilitating its integration into different machinery.

Applications

The motor mount is used in a wide range of applications, primarily in agricultural and industrial machinery. Its primary function is to provide stable support for the engine, which is crucial in environments where vibrations can affect equipment performance. This component is essential in the construction of generators, pumps, tractors, and other equipment that require a Lombardini engine to operate.

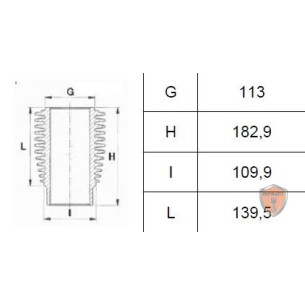

Technical characteristics

The engine mount is made of materials that guarantee adequate strength and durability. Its design allows for easy adaptation to LDW series engines, ensuring it remains in place during operation. Furthermore, its construction is optimized to withstand the most demanding working conditions, making it a reliable component for Lombardini engine maintenance.

Maintenance and care

To ensure proper operation of the motor base, it is recommended to perform periodic inspections. This includes inspecting for possible wear or damage that could affect its performance. Maintaining the motor base in optimal condition is essential to prolonging the motor's lifespan and ensuring its proper operation in the applications for which it was designed.

Conclusion

The motor base for Lombardini LDW 502, 602, 702, 903, 1003, 1204, and 1404 models is a key component in the structure of these motors. Its design and compatibility with multiple models make it an ideal choice for various agricultural and industrial applications. Ensuring proper support and seamless integration, this motor base is essential for the proper functioning of Lombardini motors in different working environments.