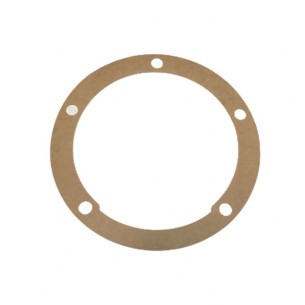

Injector nozzle (Epa-Ce 97/98) Lombardini 11LD625-3, 11LD626-3, 9LD625-2, 9LD626-2

The injector nozzle is an essential component in diesel engine injection systems, especially in the Lombardini models mentioned above. This element is responsible for atomizing the fuel, allowing proper mixing with the air in the combustion chamber, which is crucial for optimal engine performance. A detailed technical description of this component is presented below.

Model Compatibility

- Lombardini 11LD625-3

- Lombardini 11LD626-3

- Lombardini 9LD625-2

- Lombardini 9LD626-2

Main Functions

The injector nozzle performs several key functions in the fuel injection system:

- Fuel Atomization: Facilitates the conversion of fuel into small droplets, which improves mixing with air.

- Fuel Distribution: Ensures that the fuel is distributed evenly in the combustion chamber.

- Flow Control: Regulates the amount of fuel injected based on the engine's needs.

Materials and Construction

This component is manufactured with materials that guarantee its durability and resistance to engine operating conditions. The choice of materials is critical to ensuring the injector's integrity against corrosion and wear, factors that can affect its performance over time.

Applications

The injector nozzle is used in a variety of industrial and agricultural applications, where Lombardini engines are common. Its design and functionality make it suitable for heavy machinery, generators, and agricultural equipment, contributing to the proper functioning of these systems.

Maintenance and Replacement

Proper maintenance of the injector nozzle is crucial for engine performance. Periodic inspections are recommended to detect possible obstructions or wear. If a malfunction is identified, it is advisable to replace the component to ensure the engine's continued operation.

Conclusion

The injector nozzle (EPA-CE 97/98) for Lombardini models 11LD625-3, 11LD626-3, 9LD625-2, and 9LD626-2 is a vital component in the fuel injection system. Its proper operation is essential for overall engine performance, and its design is geared toward meeting the demands of various industrial and agricultural applications. Attention to detail in its construction and the selection of materials contribute to its efficiency in the operation of Lombardini diesel engines.