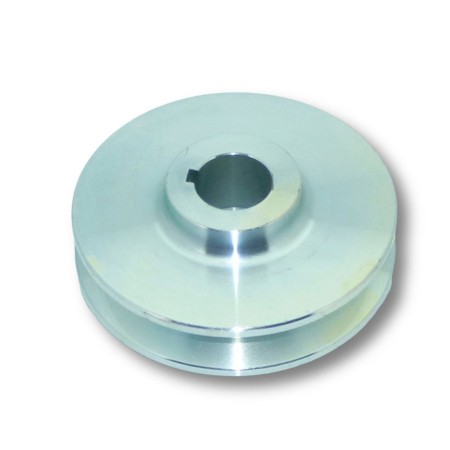

Lombardini 9LD alternator pulley

The Lombardini 9LD alternator pulley is an essential component in the power generation system of industrial and agricultural engines. This mechanical element is responsible for transmitting the engine's motion to the alternator, thus enabling the production of electricity necessary for the operation of various equipment and machinery. Its design and manufacturing are geared toward ensuring proper interaction with other engine components, ensuring optimal performance under a variety of operating conditions.

Product Features

The pulley is designed to fit precisely on Lombardini 9LD series engines, facilitating its integration into the transmission system. This component is essential for the alternator's proper functioning, as it allows the engine's rotational motion to be converted into electrical energy. The pulley is manufactured with materials that ensure adequate durability, contributing to the longevity of the system in which it is installed.

Compatibility

- Lombardini engine models: 9LD

- Applications: Agricultural equipment, electric generators, industrial machinery

The alternator pulley is compatible with a variety of applications, making it a versatile component for different types of machinery. Its specific design allows it to be used in engines of various configurations, ensuring it adapts to the needs of each user. This compatibility is crucial for those looking to maintain or repair their equipment without additional modifications.

Features and benefits

The main function of the alternator pulley is to facilitate the transmission of power from the engine to the alternator. This process is vital to ensuring the proper functioning of the machinery's electrical systems. By allowing the alternator to generate electricity, the pulley contributes to the power supply for starting systems, lighting, and other electrical components essential to the operation of the machinery.

Additionally, the pulley is designed to minimize wear and friction, helping to extend the life of both the pulley and the alternator. This is especially important in demanding work environments, where components are subjected to harsh conditions. The pulley's durability ensures that the power generation system maintains its functionality over time, reducing the need for frequent replacements.

Maintenance and care

Proper maintenance of the alternator pulley is essential to ensure its proper functioning. Periodic inspections are recommended to detect any signs of wear or damage. Preventative maintenance may include cleaning the pulley and checking its alignment with the alternator, which will help prevent driveline problems.

It is important to follow the manufacturer's recommendations regarding maintenance intervals and proper practices for the care of this component. A proactive approach to maintenance can contribute to overall system efficiency and reduce costs associated with unexpected repairs.

Conclusion

The Lombardini 9LD alternator pulley is a key component in the power generation system of industrial and agricultural engines. Its specific design and compatibility with various engine models ensure its functionality in a wide range of applications. Through proper maintenance, this component can offer reliable and long-lasting performance, ensuring that the machinery's electrical systems operate optimally.