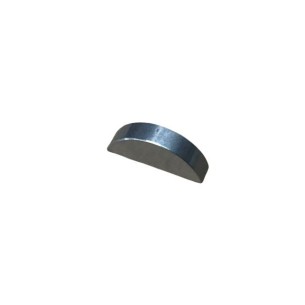

Lombardini connecting rod LDW 1204, LDW 602, LDW 903, LDW 1204/P

The connecting rod is an essential component in the operation of Lombardini engines, specifically in the LDW 1204, LDW 602, LDW 903, and LDW 1204/P models. This mechanical element plays a crucial role in converting the piston's linear motion into rotary motion, enabling efficient engine operation. Below is a detailed description of this component, its applications, and compatibility.

Product Description

The connecting rod is designed to withstand the demands of Lombardini diesel engines, ensuring a robust connection between the piston and crankshaft. This component is made of materials that ensure adequate resistance to fatigue and wear, which is essential for proper engine performance over time.

Compatibility

- Engine models:

- LDW 1204

- LDW 602

- LDW 903

- LDW 1204/P

Applications

This component is used in various industrial and agricultural applications, where Lombardini engines are common. Its design allows for use in machinery that requires continuous and reliable operation, such as generators, pumps, and construction equipment. The connecting rod is essential to ensuring the engine operates synchronously, contributing to the stability and durability of the system in which it is integrated.

Technical Characteristics

The connecting rod is precision-engineered to meet the specifications of the aforementioned engines. Its construction allows for proper alignment and movement, which is essential to minimize wear on other engine parts. Furthermore, its optimized design facilitates force transfer, contributing to engine longevity.

Maintenance and Care

To ensure proper operation of the connecting rod, and therefore the engine, it is important to perform regular maintenance. This includes checking lubricant levels and inspecting the component for possible wear. Proper maintenance can prevent failures and extend the life of the engine.

Conclusion

The connecting rod for Lombardini LDW 1204, LDW 602, LDW 903, and LDW 1204/P engines is a key component that ensures proper engine operation. Its design and construction are geared toward the needs of industrial and agricultural applications, providing an efficient connection between the piston and the crankshaft. Attention to the maintenance and care of this component is essential to ensure the operability and durability of the engine in which it is used.