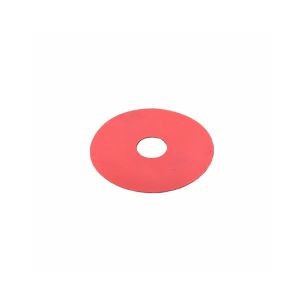

Lombardini connection tube LDW 502, LDW 502, LDW 502

The connecting pipe is an essential component in the Lombardini LDW 502 engine series. This element connects different parts of the cooling and lubrication system, ensuring proper fluid flow. Its specific design allows for efficient integration into engines in this range, contributing to the proper functioning of the system as a whole.

Compatibility

This connecting pipe is compatible with the following Lombardini engine models:

The versatility of this component makes it suitable for various applications in agricultural and industrial machinery, where an efficient cooling and lubrication system is required.

Applications

Pipe fittings are used in a variety of applications requiring the connection of fluid systems. Some of the most common applications include:

- Agricultural tractors

- Electric generators

- Construction equipment

- Gardening machinery

Its design allows it to adapt to the demands of different working environments, ensuring that the cooling system operates optimally under a variety of conditions.

Materials and Construction

The connecting tube is made of materials that guarantee adequate resistance to corrosion and high temperatures. This robust construction is essential to maintaining the integrity of the fluid system, preventing leaks and ensuring consistent performance over time.

Maintenance and Care

To ensure the longevity of the connecting pipe, periodic inspections of the cooling and lubrication system are recommended. This includes visually inspecting the pipe for signs of wear or damage. Proper maintenance helps prevent problems that could affect engine performance.

Conclusion

The Lombardini LDW 502 connecting pipe is a key component in this brand's engine series, designed to facilitate the connection of fluid systems in various applications. Its compatibility with various models and robust construction make it a reliable choice for maintaining the efficient operation of agricultural and industrial machinery. Attention to the maintenance and care of this component is essential to ensure its long-term durability and functionality.