Lombardini Cymbal 3LD450, 3LD450/S, 3LD510, 3LD510/L, 3LD510/S

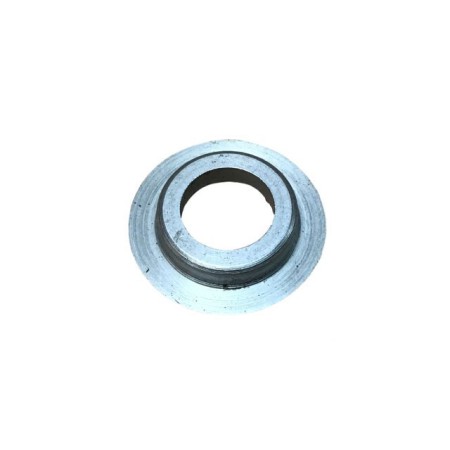

The plate is an essential component in Lombardini 3LD450 and 3LD510 series engines. This element is used in various industrial and agricultural applications, providing essential support for the operation of these engines. Below is a detailed technical description of this component, along with its applications and compatibility.

Model Compatibility

The plate is compatible with the following Lombardini engine models:

- 3LD450

- 3LD450/S

- 3LD510

- 3LD510/L

- 3LD510/S

These motors are used in a variety of machinery and equipment, highlighting the importance of the plate in their proper functioning.

Applications

The cymbal is used in a variety of applications, including:

- Electric generators

- Gardening and landscaping equipment

- Agricultural machinery

- Construction tools

Its design and functionality allow it to adapt to different work environments, ensuring optimal performance in each application.

Technical Characteristics

This component is designed to meet the demands of the 3LD series engines. Its construction allows for efficient integration with the engine systems, ensuring smooth operation. Although specifications are not detailed, it is important to mention that the plate is designed to operate under demanding conditions, making it a key element in the operation of Lombardini engines.

Maintenance and Replacement

Proper maintenance of the cymbal is crucial to ensure the longevity and proper functioning of the motor. Periodic inspections are recommended for any signs of wear or damage. If necessary, cymbal replacement should be performed following the manufacturer's recommendations to ensure compatibility and motor performance.

Conclusion

The oil pan for Lombardini 3LD450, 3LD450/S, 3LD510, 3LD510/L, and 3LD510/S engines is a fundamental component that plays a crucial role in the operation of various industrial and agricultural applications. Its compatibility with multiple engine models makes it a versatile option for those requiring a reliable replacement. Attention to maintenance and correct model identification are essential to ensure optimal performance in the work environment.