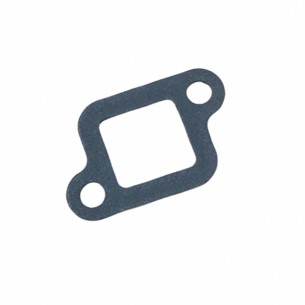

Lombardini exhaust 15LD 315 and LDW 702

The Lombardini 15LD 315 and LDW 702 exhaust is an essential component of the exhaust system for Lombardini diesel engines. This element is designed to facilitate the evacuation of gases generated during the combustion process, contributing to proper engine operation and compliance with current environmental regulations.

Compatibility

This exhaust system is compatible with Lombardini 15LD 315 and LDW 702 engines, which are widely used in industrial and agricultural applications. Its specific design allows for proper integration with these models, ensuring optimal performance under a variety of operating conditions.

Applications

- Agricultural equipment: tractors, harvesters, and other field work vehicles.

- Industrial machinery: generators, pumps and construction equipment.

- Applications in the gardening and landscaping sector.

Design features

The exhaust is made of materials that guarantee adequate resistance to corrosion and the high temperatures generated by the engine. Its design allows for proper exhaust gas evacuation, minimizing waste buildup and promoting system durability. Furthermore, its configuration is optimized to facilitate gas flow, contributing to more efficient engine operation.

Maintenance and care

To ensure proper exhaust function, periodic inspections are recommended. These inspections should include checking for possible obstructions and the overall condition of the component. Proper maintenance not only prolongs the exhaust's lifespan but also helps keep the engine in optimal operating condition.

Rules and regulations

The Lombardini 15LD 315 and LDW 702 exhausts meet emissions regulations for diesel engines, making them suitable for use in various regions requiring specific environmental standards. It is important to consider local regulations when using this component in industrial and agricultural applications.

Conclusion

The exhaust for Lombardini 15LD 315 and LDW 702 engines is a key component that ensures proper exhaust gas evacuation, contributing to efficient engine operation. Its design and compatibility with specific models make it indispensable in a variety of applications, from agricultural machinery to industrial equipment. Maintaining this system in optimal condition is essential to ensure the longevity and proper performance of the engine in which it is installed.