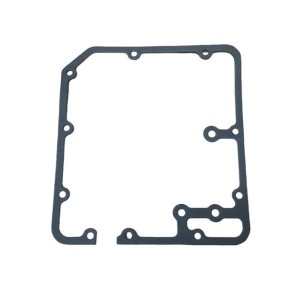

Lombardini LDW 502 thermostat-radiator tube

The radiator-thermostat tube is an essential component in the cooling system of Lombardini LDW 502 engines. This element plays a crucial role in regulating engine temperature, ensuring optimal operation and extending its lifespan. Below is a detailed technical description of this component, including its applications and compatibility.

Product Description

The thermostat-radiator hose is designed to connect the thermostat to the radiator, allowing proper coolant flow. This flow is essential for maintaining engine temperature within established parameters, preventing overheating and ensuring proper cooling system performance.

Applications

- Used in Lombardini LDW 502 engines, commonly used in agricultural machinery and industrial equipment.

- Compatible with various applications that require precise engine temperature control.

- Ideal for cooling systems in demanding environments, where reliability and durability are essential.

Compatibility

This hose is specific to the Lombardini LDW 502 engine model, ensuring proper integration into the cooling system. It is important to verify compatibility with other models in the same series or with engines that use similar components to ensure proper operation.

Materials and Construction

The tube is made of materials that offer resistance to corrosion and high temperatures, contributing to its durability under demanding operating conditions. The tube's construction ensures a precise fit and effective sealing, minimizing the risk of leaks in the cooling system.

Maintenance and Care

To ensure proper operation of the thermostat-radiator hose, periodic inspections of the cooling system are recommended. This includes checking for possible leaks, checking the condition of the coolant, and cleaning the surrounding components. Proper maintenance can prevent major problems and ensure engine longevity.

Conclusion

The radiator-thermostat hose for the Lombardini LDW 502 engine is a key component in the cooling system, designed to ensure efficient coolant flow and maintain optimal engine temperature. Its model-specific compatibility and robust construction make it a reliable choice for industrial and agricultural applications. Attention to system maintenance and regular inspection will contribute to trouble-free operation and a longer engine life.