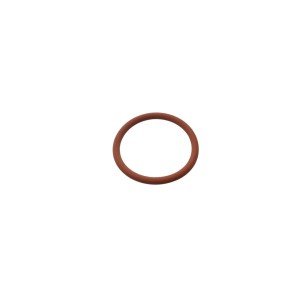

Lombardini O-ring rubber 11LD625-3, 11LD626-3, 5LD675-2, 5LD675-3, 5LD824-3/B, 5LD825-2, 5LD825-3, 5LD82

The O-ring is an essential component in machinery that uses Lombardini engines, specifically in models 11LD625-3, 11LD626-3, 5LD675-2, 5LD675-3, 5LD824-3/B, 5LD825-2, 5LD825-3 and 5LD82. This element is primarily used to ensure effective sealing in various applications, contributing to the integrity of the system in which it is installed.

Model Compatibility

This type of O-ring is compatible with a variety of Lombardini engines, making it a versatile option for the maintenance and repair of various equipment. The specific models it is compatible with are detailed below:

- 11LD625-3

- 11LD626-3

- 5LD675-2

- 5LD675-3

- 5LD824-3/B

- 5LD825-2

- 5LD825-3

- 5LD82

Applications

The O-ring is used in various applications within the aforementioned engines. Its main function is to act as a seal that prevents fluid leaks, which is crucial for the proper functioning of hydraulic and cooling systems. Furthermore, its design allows it to adapt to different mounting configurations, facilitating its integration into Lombardini engines.

Materials and Properties

This component is made of materials that offer resistance to various operating conditions. The O-ring is able to withstand temperature and pressure variations, making it suitable for industrial and agricultural environments. Its elasticity and compressive strength allow for an effective seal, minimizing the risk of leaks and ensuring the durability of the system.

Maintenance and Replacement

To ensure the proper functioning of Lombardini engines, it is recommended to perform periodic maintenance on all components, including the O-ring. Over time, natural wear can affect its sealing capacity, so it is recommended to check its condition and replace it when necessary. Proper maintenance not only prolongs the engine's lifespan but also ensures optimal operation.

Conclusion

O-rings are a key component in Lombardini engines, playing a fundamental role in sealing critical systems. Their compatibility with various models and their ability to adapt to different applications make them an indispensable choice for the maintenance of industrial and agricultural machinery. Attention to detail in the maintenance of these types of components can make a difference in the operability and longevity of the engines.