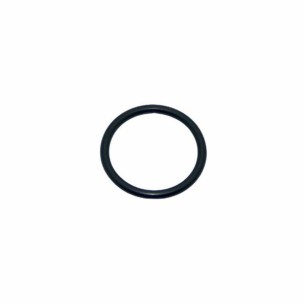

Lombardini O-ring rubber 25LD425-2, LDW 1204/T, LDW 1003, LDW 1204, LDW 1404, LDW 502, LDW 502, LD

The O-ring is an essential component in various industrial and agricultural engines, providing an effective seal in applications where leak prevention is crucial. This specific model is compatible with a variety of Lombardini engines, including the 25LD425-2, LDW 1204/T, LDW 1003, LDW 1204, LDW 1404, and LDW 502 models. Its design is optimized to meet the operating demands of these engines, ensuring a precise fit and proper functionality.

Model Compatibility

- 25LD425-2

- LDW 1204/T

- LDW 1003

- LDW 1204

- LDW 1404

- LDW 502

Applications

This type of O-ring is used in various applications within the aforementioned engines, where effective sealing is required to prevent fluid leakage. Its design allows it to adapt to different mounting configurations, ensuring optimal performance under a variety of operating conditions.

Materials and Construction

O-rings are made from materials that offer resistance to compression and deformation, allowing them to maintain their shape and functionality over time. This type of material is chosen for its ability to withstand harsh environmental conditions, making it a suitable choice for engines operating in demanding industrial and agricultural environments.

Technical Characteristics

This component is characterized by its circular design, which allows for even pressure distribution in the sealing area. The O-ring is essential for the proper functioning of engine lubrication and cooling systems, contributing to the integrity of the entire system.

Maintenance and Replacement

It is advisable to periodically inspect the O-ring to ensure its integrity and functionality. If signs of wear or damage are detected, it should be replaced to avoid engine malfunctions. Proper care of this component can prevent major system failures.

Conclusion

The O-ring for the aforementioned Lombardini engines is a key component that plays a vital role in maintaining their operating efficiency. Its design and materials ensure effective sealing, which is essential for proper engine operation in a variety of applications. Maintaining this type of replacement part is essential to guarantee the longevity and good condition of industrial and agricultural engines.