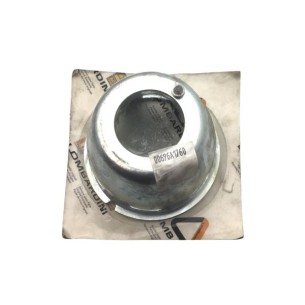

Lombardini plug 6LD325, 6LD360, 6LD400, 6LD435, 7LD600, 7LD665, 7LD740

The cap for Lombardini 6LD and 7LD series engines is an essential component in the oil and coolant tank closure system. This element is designed to ensure the tightness and protection of the fluids inside the engine, contributing to its proper operation and maintenance. Below is a detailed technical description of this product, including its applications and compatibility.

Model Compatibility

This plug is compatible with the following Lombardini engine models:

- 6LD325

- 6LD360

- 6LD400

- 6LD435

- 7LD600

- 7LD665

- 7LD740

Applications

The plug is used in various industrial and agricultural applications, where Lombardini engines are commonly employed. These engines are known for their robustness and versatility, and are used in machinery such as:

- Electric generators

- Tractors

- Gardening equipment

- Construction machinery

- Irrigation equipment

Materials and Design

The cap's design is optimized to provide a secure and effective seal. It is made of materials that ensure a long service life and resistance to adverse environmental conditions. Its construction allows for easy handling and a precise fit in the corresponding tanks, preventing leaks and contamination.

Maintenance and Replacement

It's recommended to periodically check the cap to ensure it's in good condition. A damaged cap can compromise the integrity of the engine's lubrication and cooling system, which could lead to operational problems. If wear or damage is detected, it's recommended to replace it to keep the engine in optimal condition.

Technical Considerations

When selecting a plug for the engines mentioned above, it's important to consider the manufacturer's specifications and ensure the component is suitable for the specific model. Correct plug identification ensures its functionality and contributes to overall engine maintenance.

Conclusion

The cap for Lombardini 6LD and 7LD series engines is a key component in the oil and coolant reservoir closure system. Its design and materials ensure an effective seal, contributing to the proper functioning of the engines in a variety of applications. For proper maintenance, it is recommended to perform regular inspections and replace the cap when necessary, thus ensuring engine longevity and reliability.