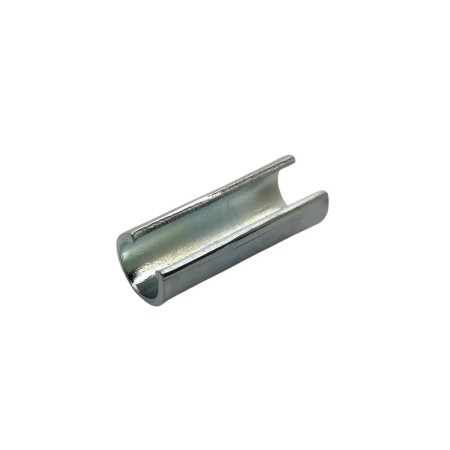

Lombardini spacer tube 11LD625-3, 11LD626-3, 12LD435-2, 12LD475-2, 3LD450, 3LD510, 4LD640, 4LD705

The spacer tube is an essential component in Lombardini engine configurations, specifically designed for the 11LD625-3, 11LD626-3, 12LD435-2, 12LD475-2, 3LD450, 3LD510, 4LD640, and 4LD705 models. This element plays a crucial role in the alignment and separation of various engine parts, ensuring proper and efficient operation of the system as a whole.

Model Compatibility

- 11LD625-3

- 11LD626-3

- 12LD435-2

- 12LD475-2

- 3LD450

- 3LD510

- 4LD640

- 4LD705

Main Functions

The spacer tube performs several key functions in the engine, including:

- Provide proper clearance between components, allowing for a precise fit and friction-free operation.

- Contribute to the structural stability of the engine, preventing unwanted movements during operation.

- Facilitate the correct alignment of shafts and other mechanical elements, which is essential for overall engine performance.

Materials and Construction

This component is made of materials that guarantee adequate durability under demanding operating conditions. The choice of materials is critical to ensuring the spacer tube maintains its integrity over time, even in industrial and agricultural environments where engines are often exposed to harsh conditions.

Applications

The spacer tube is used in a variety of applications involving the aforementioned Lombardini engines. These engines are commonly used in agricultural machinery, electric generators, and construction equipment, among others. Proper installation of this component is vital for the optimal operation of the machines that rely on these engines.

Maintenance and Replacement

To ensure proper engine operation, it is recommended to periodically inspect the spacer tube. If wear or damage is detected, replacement should be considered to avoid major system problems. Maintaining this component can prevent engine failure and extend the life of the equipment.

Conclusion

The spacer tube is a fundamental component in the structure of Lombardini engines, contributing to the alignment and separation of critical parts. Its design and construction are geared to meet the specific needs of the aforementioned models, ensuring the engine operates properly in a variety of applications. Maintaining this component is essential to maintaining engine operation and functionality in industrial and agricultural environments.