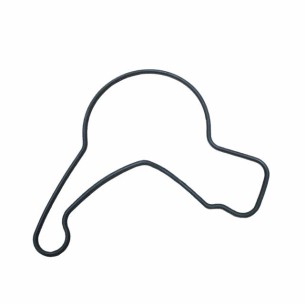

O-ring rubber 40, 95 x 2, 62 Lombardini LDW 1204/T, LDW 1003, LDW 1204, LDW 1404, LDW 502, LDW 502, LDW 50

The 40.95 x 2.62 O-ring is an essential component in machinery that uses Lombardini engines, specifically in the LDW 1204/T, LDW 1003, LDW 1204, LDW 1404, LDW 502 and LDW 50 models. This item is commonly used in applications where effective sealing is required to prevent fluid leaks and ensure system integrity.

Product Features

- Dimensions: The O-ring has an outer diameter of 95 mm and an inner diameter of 40 mm, with a thickness of 2.62 mm.

- Material: Made with materials that offer resistance to various operating conditions.

- Compatibility: Designed for use on a variety of Lombardini engine models, ensuring a precise and functional fit.

Applications

This type of O-ring is essential in hydraulic and cooling systems, where a tight seal is required to prevent fluid loss. Its design allows it to adapt to different engine components, contributing to the stability and proper operation of the machinery.

Compatible Models

The O-ring 40, 95 x 2, 62 is compatible with the following Lombardini engine models:

- LDW 1204/T

- LDW 1003

- LDW 1204

- LDW 1404

- LDW 502

- LDW 50

Importance of Sealing

Proper sealing is crucial in any mechanical system, as it prevents contaminants from entering and fluids from escaping. The O-ring acts as an effective barrier, helping to maintain internal pressure and prolong the life of engine components. Poor sealing can result in mechanical failure, underscoring the importance of using quality replacement parts with the proper specifications.

Maintenance and Replacement

It is advisable to periodically inspect the engine O-rings for signs of wear or deterioration. Proper maintenance includes checking these parts during scheduled service, which can prevent major engine malfunctions. Timely replacement of the O-ring ensures the system maintains its effectiveness and operability.

Conclusion

The 40.95 x 2.62 O-ring is a key component in the aforementioned Lombardini engines, playing a vital role in sealing critical systems. Its design and compatibility with various models ensure it is a suitable choice for maintaining the functionality and integrity of industrial and agricultural engines. Attention to detail in the maintenance of these parts contributes to optimal performance and longevity of the machinery.