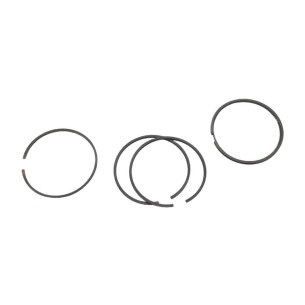

Segment set +0.50 Intermotor 1IM250

The Intermotor 1IM250 +0.50 piston ring set is an essential component in engine rebuilding and maintenance. This set is designed to provide a precise fit and proper functionality in a variety of industrial and agricultural applications. Below is a detailed description of this product, including its composition, applications, and compatibility.

Product Composition

The piston ring set consists of several piston rings used in engine pistons. Each ring is manufactured with materials that ensure proper adaptation to the engine's operating conditions. A +0.50 setting indicates an increase in ring diameter, allowing it to be used in engines that have been rebore or require specific adjustment to maintain the integrity of the combustion system.

Applications

This piston ring set is suitable for a variety of engines used in industrial and agricultural applications. Its design allows for integration into different makes and models of engines, making it a versatile option for repair and maintenance workshops. The piston rings are essential for proper sealing of the combustion chamber, which contributes to optimized engine performance.

Compatibilities

- Compatible with engines from various well-known brands in the agricultural and industrial sectors.

- Used on engines requiring a +0.50 adjustment due to grinding processes.

- Applicable in heavy machinery engines, tractors and other agricultural equipment.

Benefits of Using Piston Rings

Installing a proper set of piston rings is crucial for maintaining engine compression pressure. Effective sealing prevents compression loss and contributes to more stable engine operation. Furthermore, the use of quality piston rings can help reduce wear on the cylinder walls, thus prolonging engine life.

Technical Considerations

It's important to note that the selection of the ring set should be based on the specifications of the engine in which it will be installed. Correct identification of the diameter and ring type is critical to ensuring a proper fit. Furthermore, it's recommended to perform an engine condition analysis before proceeding with the installation of new rings to ensure there are no other issues that could affect engine performance.

Maintenance and Replacement

Regular engine maintenance includes checking piston rings. Over time, these components can wear due to friction and operating conditions. Timely replacement of piston rings helps maintain engine integrity and prevent further damage that could result in costly repairs. It is recommended that you follow the engine manufacturer's recommendations to determine the frequency of piston ring inspection and replacement.

Conclusion

The Intermotor 1IM250 +0.50 piston ring set is a key component for engine maintenance and repair in industrial and agricultural applications. Its design and compatibility with various models make it a practical choice for industry professionals. Attention to detail in the selection and maintenance of these piston rings is essential to ensure optimal engine performance over time.