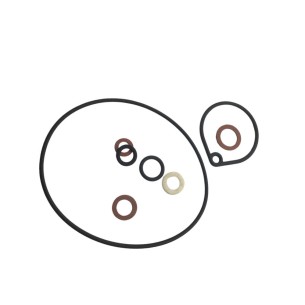

M10 Lombardini connector screw, various models

The M10 coupling screw is an essential component in Lombardini engine machinery, used in a variety of industrial and agricultural applications. This fastener features a specific design, which allows for a secure and efficient connection between different engine parts. Below is a detailed description of this screw, along with its compatibility and applications.

Product description

The M10 coupling screw is designed to provide a robust connection in mechanical systems. Its construction allows for effective integration into various Lombardini engine models, ensuring that the parts remain firmly connected during operation. This type of screw is essential for assembling components that require precise and long-lasting fastening.

Compatibility

This screw is compatible with various Lombardini engine models, making it a versatile replacement for different applications. Some of the most common models that use this type of screw include:

- Lombardini LDW 502

- Lombardini LDW 702

- Lombardini 15LD 350

- Lombardini 15LD 440

- Lombardini 15LD 480

Compatibility with these models ensures that the M10 coupling screw is a suitable option for the maintenance and repair of Lombardini engines, facilitating the availability of spare parts for users of this brand.

Applications

The M10 socket cap screw is used in a variety of industrial and agricultural applications. Its design allows for use in:

- Engine cooling systems

- Transmission component connections

- Mounting accessories and auxiliary devices

- Fixing engine casings and covers

These applications highlight the importance of the screw in the proper functioning of Lombardini engines, contributing to the structural integrity of the systems in which it is integrated.

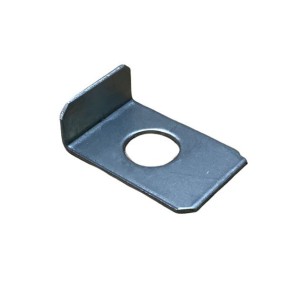

Technical characteristics

The M10 coupling screw is distinguished by its design, which allows for easy handling and precise adjustment. Its thread is designed to ensure a firm hold, preventing loosening during use. This type of screw is essential in engine engineering, where precision and reliability are crucial for proper machine operation.

Maintenance and care

To ensure the longevity of the M10 coupling bolt, it is recommended to perform periodic inspections on the engines where it is used. This includes checking the condition of the threads and the integrity of the material. Proper maintenance can prevent engine performance problems and ensure that all connections remain secure.

Conclusion

The M10 coupling screw is a key component in Lombardini engine machinery, offering compatibility with various models and applications in the industrial and agricultural sectors. Its design and functionality make it an ideal choice for those looking for a reliable replacement for their engines. Attention to detail in its manufacturing ensures it meets user demands while maintaining the integrity of the mechanical systems in which it is used.