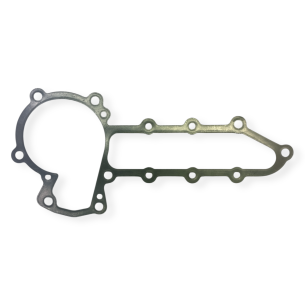

Raywin engine temperature sensor

The Raywin engine temperature sensor is an essential component for temperature monitoring and control in industrial and agricultural propulsion systems. This device is designed to provide accurate and reliable measurements, enabling effective monitoring of the engine's thermal status and contributing to optimized performance.

Product description

This sensor integrates into a wide variety of engines, being compatible with different models and brands. Its robust design and ability to operate in harsh conditions make it an ideal choice for applications in industrial and agricultural environments. The technology used in its construction ensures a rapid response to temperature changes, which is crucial for engine protection and failure prevention.

Compatibility

- Diesel and gasoline engines of various brands.

- Applications in agricultural machinery, such as tractors and harvesters.

- Industrial equipment, including generators and compressors.

Applications

The temperature sensor is used in multiple applications where thermal monitoring is essential. Key applications include:

- Temperature control in agricultural machinery engines.

- Monitoring cooling systems in industrial generators.

- Overheating detection in commercial vehicle engines.

Benefits of temperature monitoring

Implementing a temperature sensor in engines offers several significant benefits:

- Prevents damage from overheating, prolonging engine life.

- Improves operational safety by enabling early detection of anomalies.

- Facilitating preventive maintenance, optimizing service intervals.

Technical characteristics

This sensor is designed to operate over a wide temperature range, making it suitable for a variety of operating conditions. Its construction allows for simple installation in motors, ensuring effective contact with the medium being measured. Furthermore, its compact design facilitates integration into tight spaces without compromising functionality.

Conclusion

The Raywin engine temperature sensor is a key component for thermal management in propulsion systems. Its ability to provide accurate measurements and its wide compatibility make it an indispensable tool for the maintenance and operation of industrial and agricultural machinery. Constant temperature monitoring not only protects the engine but also contributes to operational efficiency and long-term cost reduction.