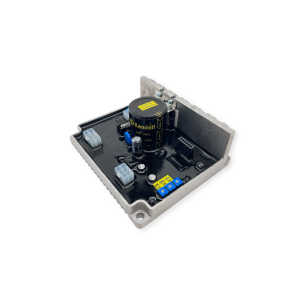

Brush holder with brushes complete alternator NSM KR80, KR100 (AVR525D)

The complete brush holder and brushes for NSM KR80 and KR100 alternators (AVR525D) is an essential component in the power generation system of these models. This component is designed to ensure proper contact between the brushes and the commutator, enabling correct electrical current transfer. A detailed description of its features and applications follows.

Product Description

The brush holder is a fundamental component that houses the carbon brushes, which are responsible for conducting electricity in the alternator. This assembly is manufactured with materials that ensure adequate conductivity and durability, allowing for optimal alternator performance under various operating conditions.

Compatibility

- Alternator models: NSM KR80

- Alternator models: NSM KR100

Applications

This brush holder is used in power generation systems requiring alternators of the models mentioned. Its specific design allows for integration into various generator and generator set configurations, ensuring efficient operation of the electrical system. It is ideal for industrial and commercial applications where a reliable power source is needed.

Technical Specifications

The complete brush holder and brushes are designed to provide a secure and stable connection. The brushes are manufactured to fit the brush holder perfectly, minimizing wear and maximizing component life. This design also facilitates brush maintenance and replacement, ensuring continuous, uninterrupted alternator operation.

Maintenance and Replacement

Regular maintenance of the brush holder is crucial to ensure the alternator functions correctly. Periodic inspections are recommended to check the condition of the brushes and brush holder, ensuring there is no buildup of debris or excessive wear. If any irregularities are detected, it is advisable to replace the component to prevent electrical system failures.

Conclusion

The complete brush holder with brushes for NSM KR80 and KR100 alternators (AVR525D) is a key component in the operation of power generation systems. Its design and compatibility with specific models ensure effective integration into various applications. Proper maintenance and periodic inspection of this component are essential to ensure continuous and reliable alternator operation.