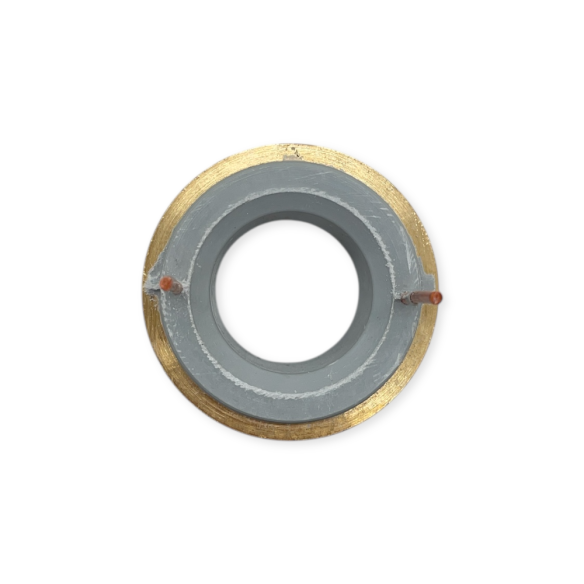

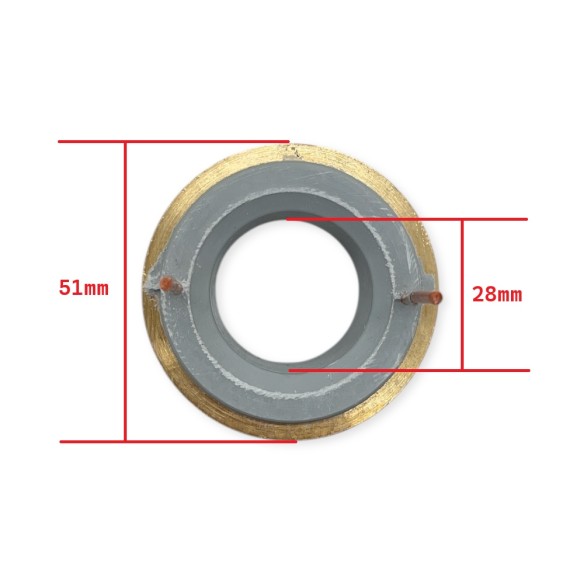

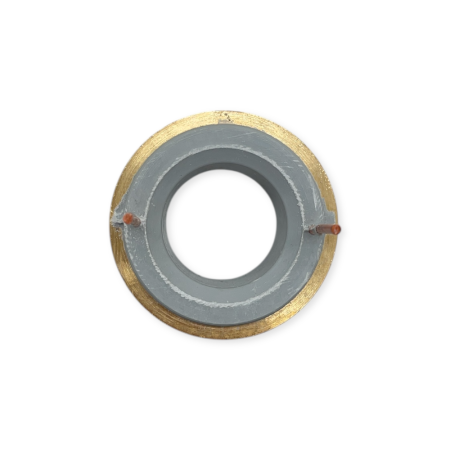

NSM 502/7 brush collector for alternator CR100, ZR100, CR112, ZR112, WS DC, WS TDC

The NSM 502/7 brush collector is an essential component for the operation of alternators in various industrial and commercial applications. This component is specifically designed for use in alternator models such as the CR100, ZR100, CR112, ZR112, as well as the WS DC and WS TDC series. Its primary function is to facilitate the transfer of electrical current between the brushes and the alternator rotor, ensuring efficient and stable contact during operation.

Model Compatibility

- CR100

- ZR100

- CR112

- ZR112

- WS DC

- WS TDC

Product Features

This brush collector is manufactured with materials that ensure proper electrical conductivity and wear resistance. Its design allows for easy installation on the aforementioned alternators, contributing to optimal electrical system performance. The collector's structure is designed to withstand the typical operating conditions of alternators, making it a reliable component for the maintenance and repair of electrical equipment.

Applications

The NSM 502/7 brush collector is used in a variety of applications where electrical power generation is required. This includes, but is not limited to, power generation systems in industrial environments, heavy machinery, and portable generators. Its versatility makes it suitable for different sectors, ensuring that alternators operate effectively under diverse conditions.

Maintenance and Replacement

Regular maintenance of electrical components, including the brush collector, is essential to ensure the longevity and proper functioning of alternators. Periodic inspections are recommended to detect signs of wear or damage, which can help prevent electrical system failures. Replacement of this component should be carried out according to the manufacturer's guidelines to ensure alternator compatibility and performance.

Conclusion

The 502/7 NSM brush collector is a key component in the operation of CR100, ZR100, CR112, ZR112, WS DC, and WS TDC alternators. Its design and construction are geared towards providing an efficient electrical connection, which is crucial for the operation of power generation systems. Proper maintenance and correct installation of this component are essential to ensure the alternator's operability in various industrial and commercial applications.