Lombardini driving pulley LDW 1204/T, LDW 1003, LDW 1204, LDW 1404, LDW 502, LDW 502, LDW 502 city

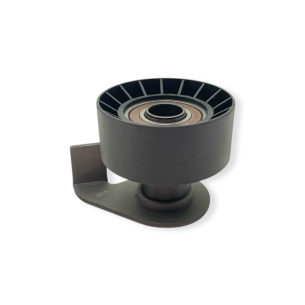

The drive pulley is an essential component of the power transmission system of Lombardini engines, specifically designed for use on the LDW 1204/T, LDW 1003, LDW 1204, LDW 1404, and LDW 502 models, including the LDW 502 City variant. This mechanical element plays a crucial role in the transfer of power between the engine and other system components, ensuring efficient and coordinated operation.

Model Compatibility

- LDW 1204/T

- LDW 1003

- LDW 1204

- LDW 1404

- LDW 502

- LDW 502 city

Applications

This type of pulley is used in a variety of industrial and agricultural applications where reliable power transmission is required. Its design allows it to be effectively integrated into machinery systems operating under demanding conditions, contributing to the overall operation of the equipment. The drive pulley is essential in the operation of generators, pumps, and other devices that rely on the mechanical power provided by the aforementioned Lombardini engines.

Technical Characteristics

The drive pulley is made of materials that ensure adequate strength and durability, allowing it to be used in a variety of work environments. Its design is optimized to facilitate connection with belts and other transmission elements, ensuring precise and efficient coupling. This component is an integral part of the transmission system, where its proper selection and maintenance are vital to the engine's operation.

Maintenance and Replacement

Regular maintenance of the drive pulley is essential to ensure the longevity of the engine and its transmission system. Periodic inspections are recommended for signs of wear or damage. If replacement is required, it is important to select the appropriate pulley that meets the specifications of the corresponding engine model, thus ensuring compatibility and proper system operation.

Conclusion

The drive pulley for Lombardini engines is a key component in power transmission, used in a wide range of industrial and agricultural applications. Its design and manufacturing are geared toward providing an effective solution for connecting the engine to other mechanical components. Attention to maintenance and proper selection of this component are essential to ensure optimal operation of the system in which it is integrated.