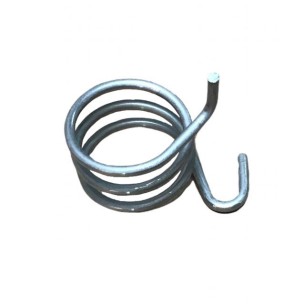

Rubber tube rocker rods Lombardini LDA 672, LDA 832 and 5LD

The rubber rocker rod tube is an essential component in Lombardini LDA 672, LDA 832, and 5LD engines. This component is designed to ensure the proper functioning of the rocker arm systems, contributing to the engine's proper operation in various industrial and agricultural applications.

Compatibility

This component is compatible with the following Lombardini engine models:

- Lombardini LDA 672

- Lombardini LDA 832

- Lombardini 5LD

Compatibility with these models ensures that the rubber tube fits perfectly to the required specifications, facilitating its integration into the rocker arm system of each engine.

Applications

Rubber rocker rod tubes are used in a variety of applications where Lombardini engines are used. These engines are commonly used in:

- Agricultural equipment, such as tractors and combine harvesters.

- Construction machinery, including generators and compressors.

- Industrial applications requiring internal combustion engines.

The versatility of these engines allows the rubber tube to be a key component in different sectors, ensuring optimal performance in each of them.

Product Features

The rubber rocker rod tube is designed to meet the demands of the aforementioned engines. This component is characterized by its ability to maintain the integrity of the rocker arm system, which is crucial to engine performance. Its design allows for proper motion transmission, ensuring the rocker rods operate efficiently.

Maintenance and care

To ensure the longevity of your rocker arm gasket, regular engine maintenance is recommended. This includes periodically inspecting the rocker arm system components and cleaning the surrounding parts to prevent the buildup of debris that could affect their operation. Proper maintenance contributes to the preservation of your rocker arm gasket and the overall efficiency of your engine.

Conclusion

The rubber rocker rod tube is a fundamental component in Lombardini LDA 672, LDA 832, and 5LD engines. Its design and compatibility with these models ensure proper operation in various industrial and agricultural applications. Attention to the maintenance and care of this component is essential to ensure its durability and the proper functioning of the engine in which it is installed.