Rocker arm adjustment screw Lombardini 5LD675-2, 5LD675-3, 5LD824-3/B, 5LD825-2, 5LD825-3, 5LD825-4, 5

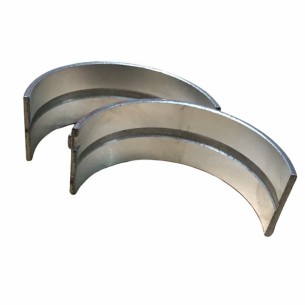

The rocker arm adjustment screw is an essential component in Lombardini engines, specifically designed for the 5LD675-2, 5LD675-3, 5LD824-3/B, 5LD825-2, 5LD825-3, and 5LD825-4 models. This mechanical element plays a crucial role in rocker arm adjustment and timing, ensuring proper operation of the engine's valve train.

Model Compatibility

- 5LD675-2

- 5LD675-3

- 5LD824-3/B

- 5LD825-2

- 5LD825-3

- 5LD825-4

Function of the Adjustment Screw

This screw allows precise adjustment of the clearance between the rocker arms and valves, which is essential for proper engine operation. Proper adjustment helps maintain synchronization between rocker arm movement and valve opening and closing, which in turn influences overall engine performance.

Materials and Construction

The screw is made of materials that guarantee adequate resistance to corrosion and wear, which is essential in demanding working environments. Its design is optimized to withstand the stresses and forces generated during engine operation, ensuring a long service life for the component.

Applications

This screw is used in a variety of industrial and agricultural applications involving Lombardini engines. Its specific design allows for integration into engine systems requiring precise rocker arm adjustment, which is common in agricultural machinery, generators, and other industrial equipment that rely on internal combustion engines.

Maintenance and Replacement

Regular maintenance of engine components, including the rocker arm adjustment screw, is essential to ensure optimal performance. Periodic inspections are recommended for any signs of wear or damage. If replacement is required, it is important to use a screw compatible with the models mentioned to ensure proper engine operation.

Conclusion

The rocker arm adjustment screw for Lombardini 5LD675-2, 5LD675-3, 5LD824-3/B, 5LD825-2, 5LD825-3, and 5LD825-4 engines is a key component in engine mechanics. Its adjustment and adjustment function is vital for the proper functioning of the valve system, contributing to the operational efficiency of various industrial and agricultural applications. Selecting the right screw and maintaining it are fundamental aspects to ensure the longevity and proper performance of the engine in which it is installed.