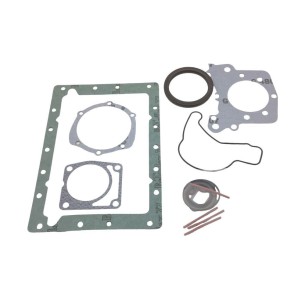

Lombardini O-ring rubber LDW 1503, LDW 1603, LDW 1204/T, LDW 1003, LDW 1204, LDW 1404, LDW 502, LDW 502

The O-ring is an essential component in machinery that uses Lombardini engines, specifically in the LDW 1503, LDW 1603, LDW 1204/T, LDW 1003, LDW 1204, LDW 1404 and LDW 502 models. This element is mainly used to ensure effective sealing in various applications, contributing to the integrity of the system in which it is installed.

Model Compatibility

This type of O-ring is compatible with a variety of Lombardini engines, making it a versatile option for maintenance and repair of different units. The specific models it is compatible with are detailed below:

- LDW 1503

- LDW 1603

- LDW 1204/T

- LDW 1003

- LDW 1204

- LDW 1404

- LDW 502

Applications

O-rings are used in various applications within the aforementioned engines, playing a crucial role in sealing fluids and gases. Their design allows them to adapt to different spaces and conditions, making them ideal for use in industrial and agricultural engines. This component is essential for maintaining the functionality of hydraulic and cooling systems, as well as in other circuits where effective sealing is required.

Materials and Properties

O-rings are generally made of materials that offer resistance to various factors, such as temperature and pressure. This ensures that the component maintains its shape and functionality over time, even under demanding conditions. Selecting the right materials is crucial to ensuring the seal remains effective throughout engine operation.

Maintenance and Replacement

Regular maintenance of engine components is essential to ensure proper operation. The O-ring, as it can wear out over time, should be checked periodically. If signs of deterioration are detected, it is advisable to replace it to prevent leaks that could compromise engine performance.

Technical Considerations

When selecting an O-ring for Lombardini engines, it is important to consider the dimensions and specific application type. Correct selection of the O-ring size and material is critical to ensuring a proper seal. It is also advisable to consult the manufacturer's technical documentation for detailed information on the specifications and requirements for each model.

Conclusion

The O-ring is a key component in the maintenance of Lombardini engines, ensuring effective sealing in a variety of applications. Its compatibility with multiple models and its ability to adapt to different conditions make it an indispensable option for the proper functioning of these engines. Proper maintenance and replacement of this component are essential to ensure the longevity and optimal performance of the machinery.